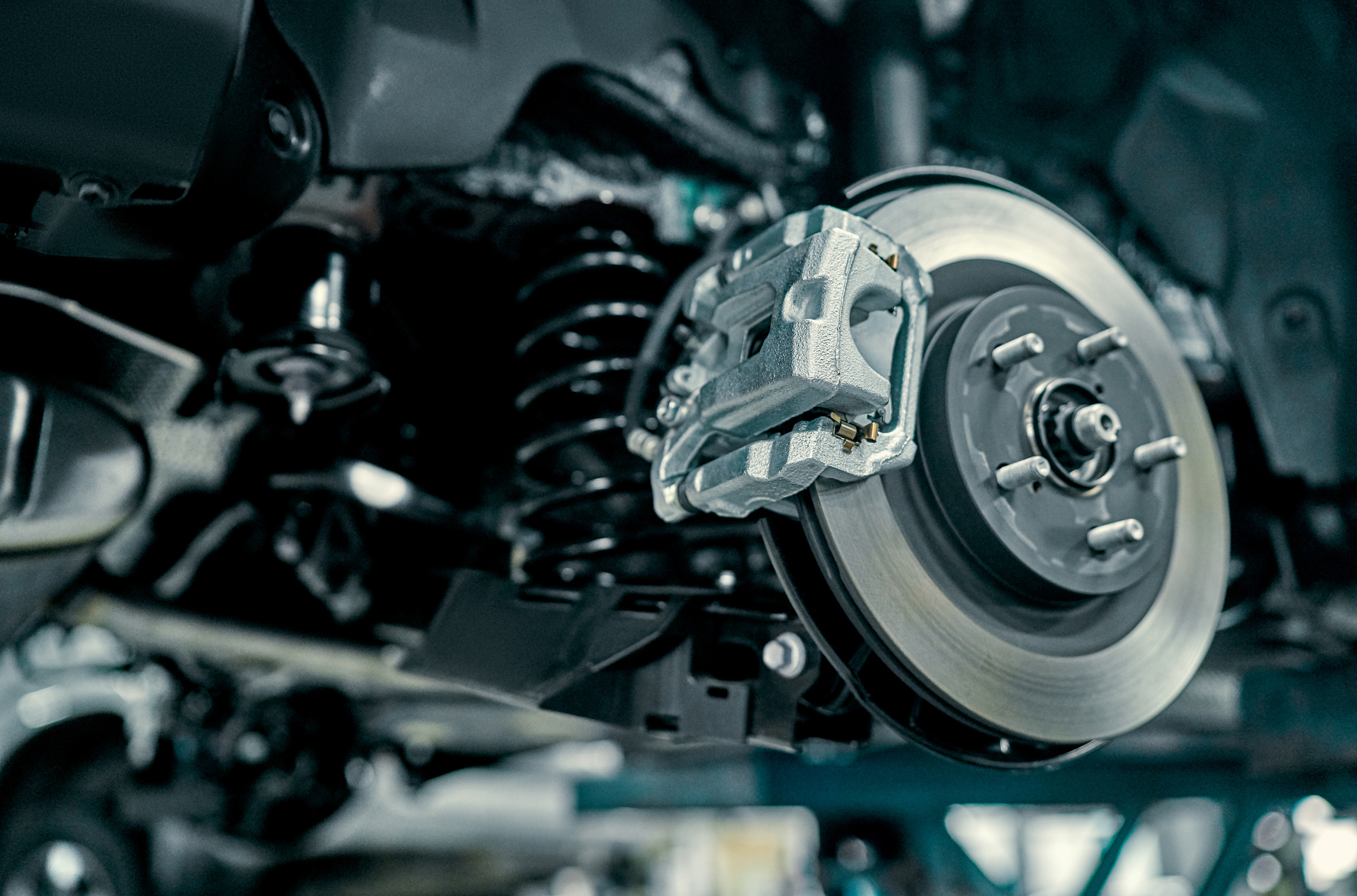

Both brake pads and brake discs are consumables. They must be regularly replaced to ensure proper operation of the brakes. The replacement procedure is not complicated; however, to ensure that it is done properly, a good idea is to have it done by professional mechanics.

The fundamentals of brake pad and brake disc replacement

Similarly to suspension springs, shock absorbers or tires, you should always change the brake pads and brake discs on both wheels of an axle, even if the corresponding parts on the other side of the axle look decent. This will ensure even braking on both wheels, which may be of great importance, especially in emergency situations. If the brake pad lining on one side wears out faster than on the other, or if one of the discs goes rusty, make sure to check the brake callipers for dirt and rust.

How do you know when to change the brake pads?

Brake pads require replacing when the lining is less than 2 mm thick, unless a different value is indicated by the manufacturer. How do you know that the pads are almost completely worn out? Surprisingly, even worn out lining is capable of effectively stopping the car without affecting the braking efficiency.

The most common sign indicating that the pad lining is worn out is a metallic squeaking sound attributed to a small piece of metal attached to the brake pad plate. The sound it produces is a warning to the driver that the brake pad lining has become too thin. You should never ignore this sound. Newer cars are equipped with electronic lining thickness sensors, which make a dedicated control on the dashboard go off after the pad lining wears out.

Another sign of a brake pad wear may be a low level of the brake fluid. When activated, the brake fluid control does not necessarily indicate a leakage. The brake fluid level decreases as the brake pistons are pushed out and replaced by the fluid. The fluid goes back to the normal level after new pads are fitted. Remember, though, that the brake fluid is highly hygroscopic, and that too high water content decreases its boiling point. So, when replacing brake pads a good idea is to check the fluid level by means of a gauge (app. PLN 20-30) and, if necessary, replace it with a suitable fresh fluid.

Two sides of a brake disc

The formation of a flange on the outer edge of a brake disc is a common sign of brake disc wear. The flange is formed as the central part of the disc surface becomes thinner due to lining operation. The disc wear can be measured by means of a regular slide calliper. Brake disc manufacturers allow for a small material loss of app. 1 mm per each side of the disc.

You should also keep in mind that it is not just a reduction in the thickness of a brake disc that calls for its change. You should also pay attention to any cracks, corrosion and discolouration indicating metal overheating. Importantly, corrosion affects particularly the inner side of a brake disc, hence seemingly good condition of the visible part may be deceptive. In addition, a disc may be bent, but you need a dial gauge to determine that. When changing discs, remember to change them together with the pads. Otherwise, the old pad lining may cause damage to the smooth surface of the new discs, thus affecting their performance.

What is the useful life of brake pads?

Make sure you change the brake pads before they reach the wear limit. Thin lining easily overheats and crumbles, rendering your car useless when you least expect it. It is assumed that brake pads should be changed when the lining is less than 3 mm thick. How long should new brake pads last, though? Much depends on your driving style, your car’s weight, the terrain you drive on and the friction material on the pads. It is assumed that a good-quality brake pad should last app. 50-70 thousand km. The cheap ones usually fail after app. 20 thousand km. Given the short time needed to change them, it’s really not worth to save money on them. If you’re always looking for what’s best for you, you should choose pads by well-known brands such as ABE or ABE Performance.

Careful with the brake hoses!

To access the brake discs, you need to remove the entire brake calliper. Undoing the screws may pose some trouble as they often get jammed due to high temperature and rust. So, before you remove them, spray the thread with a penetrant to loosen up the screws. After removing the calliper, do not place it on the floor or a shelf, as it is connected to a brake hose. Hanging it on the hose is a frequent mistake that may cause the hose to break. To prevent this, hang the calliper on a suspension element e.g. the spring by means of a cord or a clamp. A good idea is also to inspect the brake hoses. If they are brittle, stiff or cracked, they need changing. Choose from a wide range of the ABE hoses to make sure you buy the best quality product at an affordable price.

New installation kit

When changing the brake pads a good idea is also to change the installation kit. If you fit the old guides and plates back in place you ran the risk of the calliper not working properly. You will hear squeaky sounds and experience runout on braking and, in some situations, you may even cause damage to the new pad lining. A new installation kit is not expensive and will save you some serious trouble. If you see a brake fluid leak near the piston, you should also change the rubber sealing elements shielding the calliper from dirt. You will find all the parts you need in your brake repair kit.

Remember to push the brake piston in

When changing the pads, you must not forget to push the brake piston in. Otherwise the new pad will not fit in the calliper. Professional garages use special presses to push brake pistons in, but you can also do it using two ring spanners. Screw-in brake pistons are an exception. You can buy the required tools from Inter Cars, the leading spare-parts distributor in Poland. Place the piston on something flat or an old brake pad to avoid damaging it.

Before pushing the piston in take a look under the gasket. You will most likely find a lot of dirt there. If you push the piston in, the dirt will get into the hoses and may affect the operation of the valves. Therefore, clean the area under the gasket and then gently lubricate it with a special brake system lubricant. Also remember that some cars must be connected to a computer or disconnected from the master cylinder. Otherwise, pushing the piston in may prove impossible and even be dangerous.

Clean the discs before installation

A weaker braking force after changing the brake discs is a perfectly normal phenomenon. The new parts take time to run in before they become fully functional. A special layer applied on the ABE pads ensures a perfect fit between the pads and the discs, and reduces the run-in time to minimum. However, sometimes poor brake performance results from wrongly installed discs. Most models are covered with an oil protecting the discs against corrosion. This protective layer is used for storage purposes only and should be removed prior to installation. You can remove it by means of a brake disc cleaner. Make sure you do it before you place the discs on the hub to make things easier. Some discs, e.g. AB Performance, do not require removal of the protective layer. You will find appropriate information to this effect on the packaging. But a good idea is to clean the whole unit after completing the installation.

Is changing brake pads and brake disc by yourself a good idea?

You can easily do it by yourself – provided that everything goes smoothly and you have the appropriate technical facilities at hand. The problem appears when you have to evaluate the condition of the guides, change the piston, remove a jammed screw or remanufacture a rusty calliper. Improper installation may cause some inconvenience, e.g. runout on braking, squeaky noise or pulling of the car to one side. The cost of changing brake pads in a professional garage is relatively small, therefore you should leave this task to experts, who will also take a glimpse at some other parts, such as wheel bearings, shock absorbers or brake hoses.