Brake discs are consumable parts that require regular replacement. They are one of the most important parts responsible for the safety of the driver and passengers. That is why we have conducted numerous tests of ABE discs. What are their results?

New ABE brake products – the ABE PERFORMANCE – have arrived at Inter Cars S.A

Since it is always a good idea to choose proven quality products when deciding to replace brake pads and discs, when creating our offer we were focused exclusively on comfort, quality, and safety during braking. To authenticate the quality of parts from the ABE PERFORMANCE line, we decided to subject them to long-term quality and performance tests at the independent testing center. For this, we chose a Polish company professionally engaged in automotive research and training called BETiS.

In our series of articles about ABE PERFORMANCE, we will try to show you the process of research and testing, that will confirm the high quality of our parts.

Which brake discs and pads to choose?

Deciding to replace brake pads and discs, it is always recommended to choose proven quality products. An attractive price is one of the main criteria for choosing a spare part, but can a high-quality product and an attractive price be combined? Yes, the ABE Performance line is just such a solution, the quality and durability of which are confirmed by our long-distance tests conducted with popular car models.

How did ABE Performance Parts Tests look?

Preliminary tests before installing brake discs and pads

The first stage of testing is basic tests, that determine preliminary parameters such as dimensions, the parallelism of planes, lateral runout, etc. The results of preliminary tests confirm that ABE Performance products meet the requirements of manufacturing accuracy.

Checklist of preliminary tests performed:

- check the visual condition of the brake discs and brake pads;

- measurement of brake disc thickness by using a micrometer;

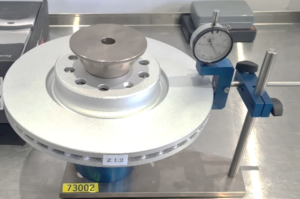

- measurement of the parallelism of the brake disc planes using a professional measuring device;

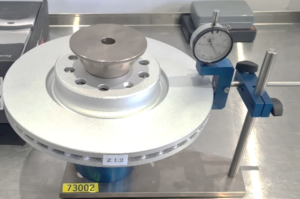

- measurement of axial runout of brake discs using a professional dial gauge;

- the condition of the brake discs and pads before installation.

Fot. 1. Measurement of parallelism of planes Z1.1 i Z1.2

Fot. 2. Measurement of disc thickness Z1.1 i Z1.2

and assessment of parameters. It should be stated that the results obtained are in accordance with the ECE R90 approval guidelines. Moreover, the measured parameters of plane parallelism and axial runout before and after installation are within acceptable ranges.

After verification of preliminary tests and positive measurements of the parallelism of planes and axial run-outs of brake sets, and after installation in test cars, it is concluded that the brake sets: C3W039ABE-P, C3S012ABE-P, 3CR049ABE meet the manufacturers’ initial quality and assembly criteria corresponding to original components.

Next steps in testing brake discs and pads

The next steps will be the evaluation of individual sets of brake pads and discs during the operation. Experts from the Bureau of Technical Expertise and Training will assess the quality of ABE Performance brake discs and pads in practice in terms of braking performance, comfort of use, and wear rate. The several stages of the tests will be documented after the distance has been covered (multiple verifications every 5,000 km). The final stage of verification will be detailed material tests, which consist of cutting the brake discs and checking the parameters of the chemical composition of the steel used and the hardness of the materials. We will share the progress and results of our tests on an ongoing basis so that our products can be chosen and recommended to customers with full responsibility and confidence. The tests were carried out by an independent research agency located in Poland called BETiS.

Quality tests of ABE brand products are also regularly conducted in the modern laboratory, Intermeko Europe, which professionally tests automotive parts and components.