The very first brake pads applied in cars were simple pieces of wood covered with leather. And they would be changed by a shoemaker, not a car mechanic. The modern brake pad linings are made of much more durable friction materials whose quality is confirmed by the ECE R90 certification in Europe.

Implementation of the ECE R90 certification

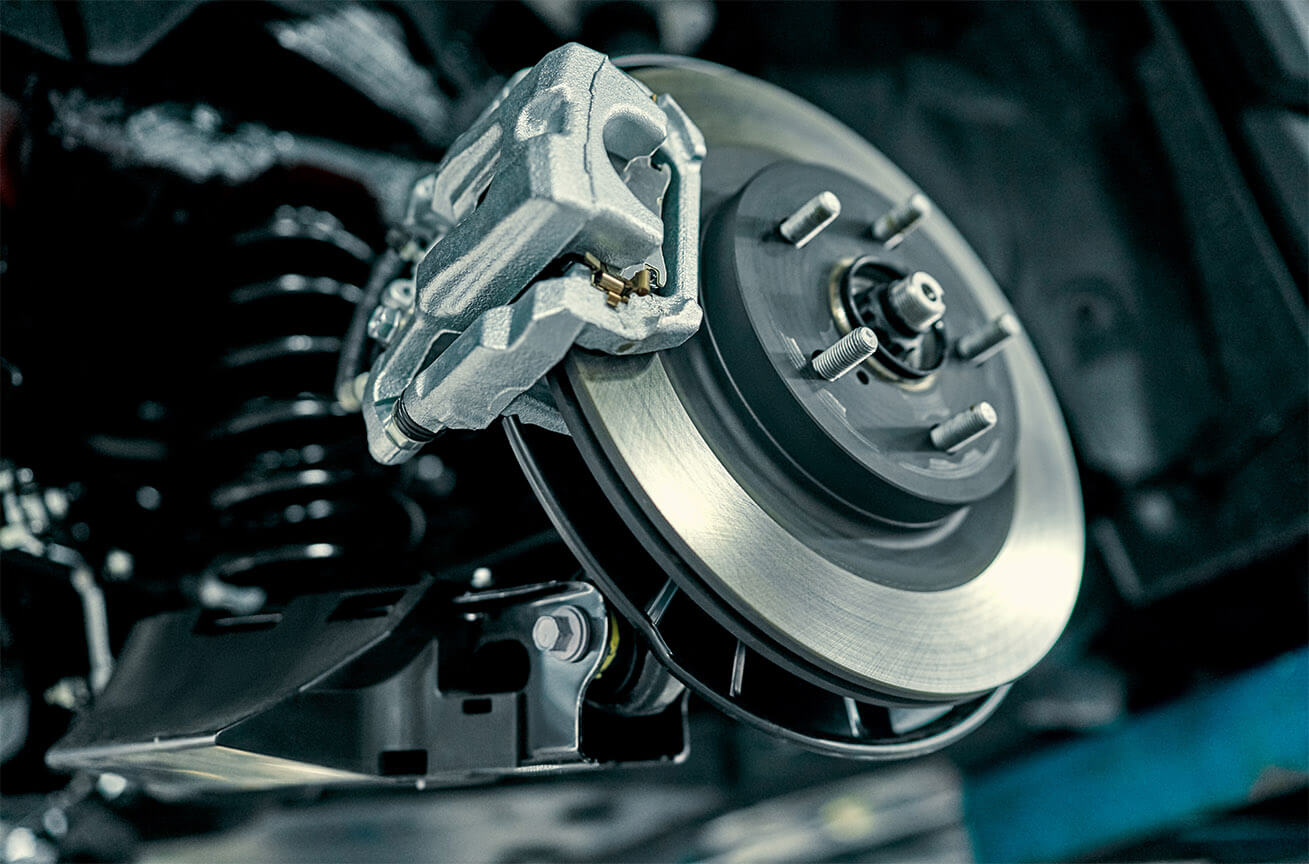

Brake pads are a key component of the braking system. Their quality impacts the braking efficiency, brake performance, safety during emergency braking and comfort of travelling. The pressure exerted by brake pads during braking should be even 4 times greater than that needed for the car to gather speed. The small surface of a pad must then provide a friction sufficient to put a car travelling at the speed of even 250 km/h to a stop.

The OE/OES pads used for first assembly undergo a tight quality control. The factory-fitted parts bearing the manufacturer’s logo undergo months of testing, as a result of which they offer top-quality and predictable performance (e.g. after wearing or overheating). But spare parts have not always been subject to such tight quality control standards. Consequently, the market was full of parts of poor or unknown performance. The ECE R90 standard was created to eliminate such parts. The standard applies to aftermarket parts and does not impact the manufacture of first-assembly brake pads. All manufacturers who want to sell their products in Europe must meet the certification standards. This regards also ABE. Our parts undergo multiple tests and are manufactured in the best, certified plants to guarantee their reliability and top quality.

Which vehicles does ECE R90 apply to?

Unification of the brake pad quality requirements was an important step toward improving part safety. The ECE R90 standard applies to all M1, M2 and M3 class vehicles registered after 1 January 1999. These include passenger cars, utility cars and buses up to 3.5 t. The provision imposing the obligation to obtain a type approval for aftermarket parts was included in Annex 15 to the Commission Directive 98/12. The directive applies to all counties of the so-called old EU and to the Czech Republic, Croatia, Slovenia, Slovakia, Russia, Ukraine, Latvia, Estonia, Romania and Hungary. It may also apply outside Europe e.g. in Japan, USA and Australia.

How are brake pads tested in conformity with ECE R90?

An R90 certificate may be issued only by a specialized certification body as all pad models are laboratory-tested and undergo a variety of stress tests. The following is measured during an ECE R90 certification procedure:

- pressure sensitivity,

- speed sensitivity,

- brake fade (loss of braking force due to high temperature).

The friction material tests last from 3 to 5 hours, much shorter than in the case of first-assembly parts. Mass produced brake pads undergo even more stringent tests, including temperature sensitivity, wear, noise levels or thermal conductivity. These tests may take up to several months to complete. The R90 standard is sufficient to determine the minimum parameters of brake pads required to obtain a safety guarantee. The friction material may not contain asbestos.

The test results may not deviate from the nominal values by more than 15%. However, if you’re looking for brake pads with parameters identical with those of the original parts, choose OEM pads. OEM are parts manufactured by the same plants and in the same technology as OE, but they bear the manufacturer’s logo, not the car brand name. You should go for top-class products that meet the requirements of even the most demanding drivers, e.g. ABE Performance brake discs and pads.

Where to find information about the ECE R90 certification?

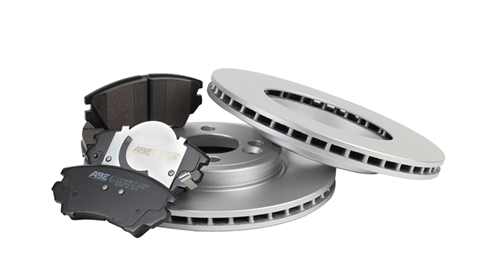

The information is included on the packaging and on the back of a pad. The code contains the number of the body confirming that the R90 standard is being conformed to, the issue number of the regulation, the friction material and the type of the mounting plate used. New parts originating from a trusted source are secured with a seal. This way you know for sure that they have not been used or opened before, and that the package contains additional components and an installation guide.

New type approval for brake discs

For a long time, the ECE R90 standard related only to the quality of brake pads and discs. However, you should keep in mind that braking performance depends also on the quality of brake discs. If their surface is uneven or they are made of a material susceptible to damages, even high-quality OE/OES pads will fail to ensure comfort and safety. Therefore, the regulation was updated to include the requirements related to brake drums and discs.

The new version of the type approval – R90-02 has been in force since November 2016. According to the new standard, all brake discs and drums available as replacement parts for newly registered cars must also undergo laboratory tests. Thank to this change, the purchaser is sure that replacement parts have a quality similar to that of the original parts. In some cases laboratory test results indicate that the replacement parts have higher parameters than the first assembly parts. ABE products have the R90-02 type approval and conform to the stringent regulations imposed by the European Union.

Why should you remember about ECE R90?

Thanks to the quality standards related to brake pads, discs, shoes and drums, finding a good-quality replacement part is easy. Even the economy parts ensure a minimum level of safety. However, we suggest that you choose the best and most advanced replacement parts using, among other things, the scorching technology. The quality of the friction material mix affects not only braking but also modulation, comfort of travelling (no squeaky sounds or vibrations) and behaviour of the lining after wearing. The cheapest brake pads heat up relatively fast and may even crack. Therefore, for safety reasons, you should choose better quality products for better comfort and safety. Choose wisely, choose ABE!